This controller unit can adjust the fuel by 0-5 volt signal, MAF frequency, or other inputs.

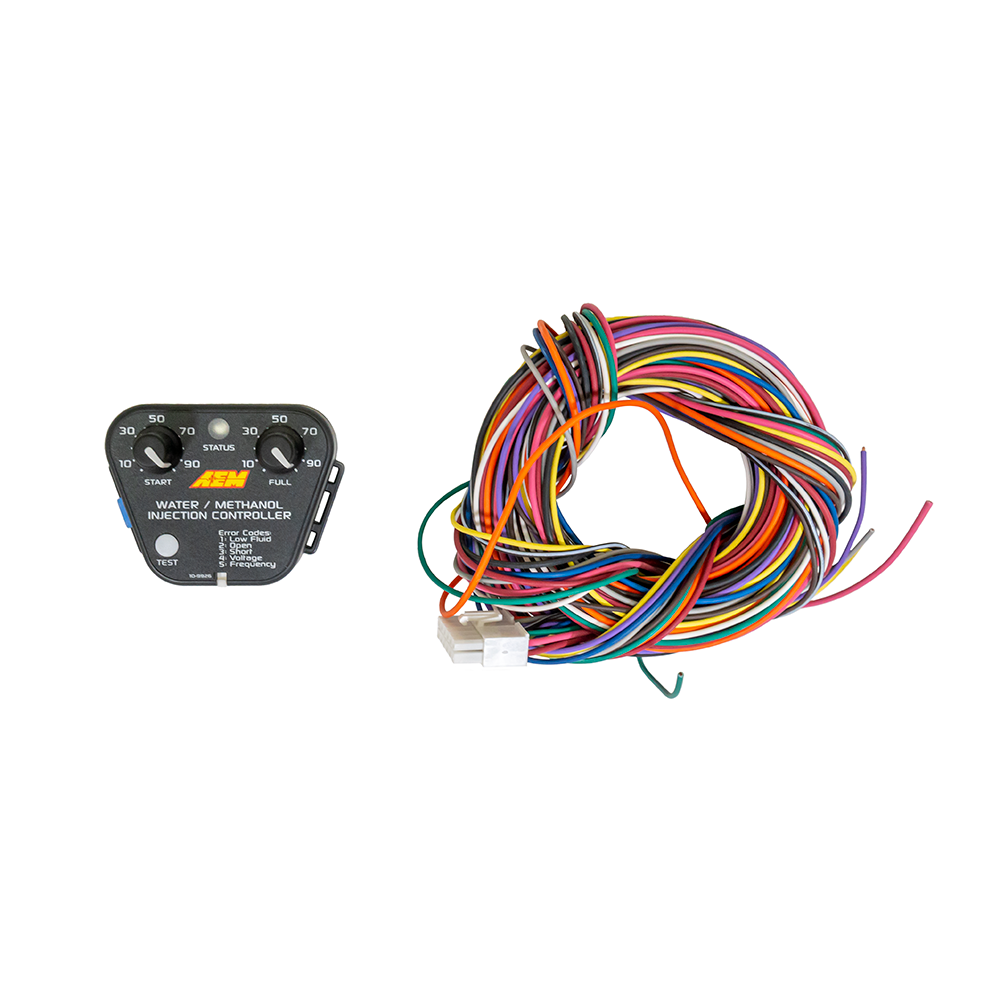

AEM's Multi-Input water/methanol injection controller features a multiple input design that enables users to install it on both high compression naturally aspirated vehicles (NA) via the MAF/IDC settings and ultra-high boost vehicles (above 35 PSI) using an external MAP sensor. The Multi-Input controller works with an external 0-5 volt voltage-based external MAP sensor, a frequency based input for Injector Duty Cycle (IDC), frequency-based mass airflow (MAF), or a 0-5 voltage-based MAF. The controller design features large, turn-resistant knobs and larger numbering to easily set accurate start and full activation points, with covered status LED and test buttons for added splash resistance.

A plug is integrated into the controller housing for mating to the redesigned wiring harness's positive-lock connector. The Multi-Input controller has an easy-to-remove plug covering the programming dipswitches and a programming legend on the back for the 0-5 volt and frequency based settings. The controller housing features an easy to access integrated fuse and molded mounting tabs. AEM's engineers spent extensive time developing the controller's flow control strategy for a more linear flow output delivery. This means that the flow delivery better matches an engine's need for water/methanol injection, which further optimizes charge air cooling and detonation control on gasoline engines or EGT reduction on turbo Diesels. AEM's Water/Methanol Injection wiring harness for the Multi-Input controller is terminated with a positive-lock connector on one end and has color-coded wires to ease installation.

Both the power and ground wires for the pump are included in the harness which simplifies the wiring process and eliminates any chance of the pump accidentally activating from a short in the system. An additional wire is included for adding an optional on/off solenoid to stop fluid flow when the system is inactive.